Windows 10 Home Product Key Free Download 2023

Windows 10 Home Product Key is a universal app that forms the foundation of many personal experiences worldwide. It has a user-friendly interface, security features, applications, and features that meet the needs of people and users. At the heart of Windows 10 Home is a key, a useful alphabetic code that allows and unlocks the operating system.

This important product acts as a digital passport, ensuring that your copy of Windows 10 Home is valid and legitimate. Users may experience restrictions or limitations when operating their systems without the correct product key. This article aims to highlight the importance of Windows 10 Home Essentials, explain its role in the overall user experience, and provide guidance for successful installation and operation. Whether you’re a new Windows 10 Home user or looking to upgrade your system, understanding the importance of key components is essential for a smooth and safe journey.

What is a Windows 10 Home Product Key?

The Windows 10 Home product key is a unique identification card to activate and authenticate this computer’s Windows 10 Home edition code. It acts as a digital license, confirming that you own a legal copy of the work. When installing Windows 10 Home, you will usually be asked for this key during installation. Once logged in and authenticated, the core unlocks the entire functionality, allowing you to adjust settings, get updates, and access various features.

You need to differentiate between stock and public keys. When a product key is used to install or activate Windows for the first time, the activation key, also called a digital license, turns on your unique system. When Windows first starts, function keys are generally set up and linked to devices. It means that even if you reinstall Windows on the same computer, Windows will boot again without reinstalling any major components.

Legal Implications of Using A Product Key

From a legal perspective, using items you did not purchase or obtained illegally can have serious consequences. Sharing or using fake or unauthorized keys is considered software piracy and a crime. Microsoft strictly monitors and enforces the licensing of its licensed software, and unauthorized use of product keys may result in penalties, including system downtime or legal action.

Simply put, a Windows 10 Home key is a unique code to unlock and authenticate your copy of Windows 10 Home. It differs from an activation key that ties your computer hardware to the operating system. Legal action is essential to ensure compliance with software licenses and avoid illegal piracy.

Why Do You Need a Windows 10 Home Product Key?

Windows 10 Home Essentials does a lot of useful things for users. First, it unlocks the operating system, ensuring your Windows copy is safe and legal. It is important to avoid legal issues and access all the features and functions that Windows 10 Home offers.

Second, a product key gives you access to Microsoft support and regular updates. Microsoft continues to release security patches, bug fixes, and feature enhancements to improve your system’s overall performance and security. You must take important steps to receive these updates, which are important for protecting your computer from malware and other threats.

Finally, a product key provides access to customization and security features. The new Windows 10 Home Essentials allows users to change the wallpaper, theme, and settings to personalize their desktop. In addition, it enables basic security features like Windows Defender, which can help you protect your data and privacy from online threats.

Tips for Safeguarding Your Windows 10 Home Product Key

Protecting your critical Windows 10 assets is important to ensure your operating system’s and personal data’s safety. First, it must be kept in good condition. Consider keeping physical copies in a lock or safe and creating digital backups of encrypted files stored on a secure cloud service or external drive. That way, you’ll have a backup if you lose your health.

If your items are lost or stolen, you can take steps to get them back. If you have Windows 10 proof of purchase, call Microsoft support. They can help you get the key back. If you updated from an older version of Windows, your main product is linked to a Microsoft account. It means that when you sign in to a new computer, Windows 10 will automatically start up. You can protect your Windows 10 home computer and operating system using these tips. Following these tips, you can protect your Windows 10 home device and operating system.

How to Activate Windows 10 Home Using Your Product Key

Maintaining Windows 10 Home Essentials is a simple task that keeps your operating system current. To get started:

- Find your product key, usually on a sticker on your computer or in the confirmation email if you purchased a digital copy.

- Open the settings menu, click the Start button, then click the Run icon.

- Select “Update and Security” from there and click the “Enable” button in the left menu. You will now see the option to restore your important items.

- Write carefully and make sure there are no mistakes.

- Click Next, and if the key is correct, Windows will open.

But don’t worry if you need help opening. There is a general solution. First, ensure you use the right product compatible with your Windows 10 Home Edition. Double-check for errors or mistakes. If it doesn’t work, try using the open “Solve” option, which may resolve the activation issue. Also, stay within zero for your products.

Troubleshooting Common Activation Issues and Reactivating after hardware changes

If you make major changes to your computer hardware, such as replacing the motherboard, you must restart Windows 10 Home. In this case, you can use the tool, but you need to contact Microsoft Support for help, as hardware updates will have to be performed again to support written permissions.

In short, installing Windows 10 Home on a basic device is a simple task, but it is important to follow the process carefully. If you experience problems, there are troubleshooting options, and if necessary, you can use Microsoft Support to restart after updating your hardware. It keeps your Windows 10 Home up-to-date and efficient.

Windows 10 Home Product Key Features

Windows 10 Home is a versatile, easy-to-use operating system to enhance your computing skills. Some of the great features that make Windows 10 Home a great choice for home users include:

- Start Menu: Windows 10 Home brings back the familiar Start Menu, which makes it easy to access your favorite apps and files when you install Live Tiles for the latest update.

- Cortana: Microsoft’s digital assistant Cortana integrates with Windows 10 Home to let you complete tasks, send messages, and search for information using voice or text commands.

- Microsoft Edge: Enjoy fast, secure web browsing with Microsoft Edge, which includes built-in Cortana integration, browsing search, and web tools.

- Virtual Desktops: Improve workflow and create different virtual desktops to allow you to switch between different tasks and projects.

- Windows Ink: Whether you have a touchscreen or a stylus, Windows 10 Home supports Windows Ink, making it easy to draw, write, and write directly on the screen.

- Game Features: Gamers will appreciate the DirectX 12 support for Xbox app settings, game mode, extended play, and access to Xbox Live.

Extra Features

- Security: Windows 10 Home comes with Windows Defender Antivirus to protect against malware and viruses. It also regularly updates security to keep your system secure.

- Universal apps: Access various apps from the Microsoft Store, including universal apps that work seamlessly across devices such as PCs, tablets, and smartphones.

- Creation Center: Connect with Action Center, which provides easy access to information, programs, and creative activities.

- Cortana Integration: Use Cortana to find files, make appointments, and answer questions, all from the desktop.

- Consistency: Windows 10 Home adapts to your device, laptop, tablet, or 2-in-1, providing a smooth and comfortable experience.

- Organize multitasking: Snap Assist lets you quickly organize and manage open windows, while Task View lets you switch between empty tasks.

- Windows Hello: Sign in securely with facial recognition, fingerprint, or PIN verification; traditional passwords are unnecessary.

- BitLocker: Protect your data with BitLocker encryption, which helps to protect your files and folders.

- Automatic updates: Windows 10 Home automatically installs updates to ensure you have the latest features, security fixes, and improvements.

Frequently Asked Questions

What is Windows 10 Home Essentials, and why do I need it?

A Windows 10 Home product key is a unique 25-character code issued by Microsoft that is required to activate and use your copy of Windows 10 Home. It works as a digital license, allowing you to use all the work functions. It would be best to have the basics to activate Windows Home 10 on your PC to ensure your copy is valid and legitimate.

Can I use Windows 10 devices on multiple computers?

No, Windows 10 Home Essentials is usually licensed on a single computer. Using the same key on multiple computers may violate Microsoft’s license terms and cause installation problems. If you need Windows 10 on multiple devices, purchase a separate license for each.

What Should I Do if I Lose Windows 10 Home Essentials?

You’ll need to purchase a new license if you’ve lost Windows 10 Home Essentials and it’s not associated with your Microsoft account. However, if you associate your product number with your Microsoft account during this process, you can restore it by signing in to your account on your computer.

Can I Upgrade to Windows 10 Home Kit?

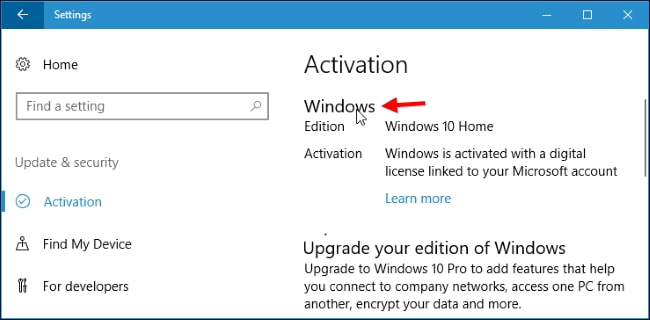

Yes, you can change Windows 10 Home settings. To do this, go to “Settings” > “Update & Security” > “Activation” and select “Change Product Key”. Follow the instructions to sign in to the new product, and Windows will attempt to activate it with the new password.

What if I Don’t Activate Windows 10 Home With My Product Key?

If you activate Windows 10 Home with the correct product key, your access will be unlimited. You will not be able to update your desktop and will be prompted temporarily to activate it. In addition, certain features may be blocked or restricted. To take advantage of all features and updates, it is recommended to activate Windows with a product key.

Conclusion

Windows 10 Home Essentials cannot be understated as its significance cannot be overemphasized. Acting like an unlock key for all the features and security updates needed for a professional experience, Windows 10 Home Essentials acts like a key that opens all features within your operating system and unlocks them all simultaneously. For an optimal experience, we strongly suggest users select genuine products obtained through official sources that conform with license agreements in terms of security or pirated software protection; instead, they should opt for legitimate ones to support developers while optimizing performance, security, and performance ensuring optimal experience across your OS system for maximum enjoyment as peace of mind & smooth running operation of system and users peace of mind!